Setch Oil Works

Setch Oil Works were planned as "the largest retorting, condensing, and refining plant in England", but construction began on an ambitious scale before a practical process had been developed to produce oils from the local shales. Despite extensive experimentation, it proved impossible to efficiently produce oils that did not retain an unacceptably high level of sulphur. As a consequence, the works were never completed.

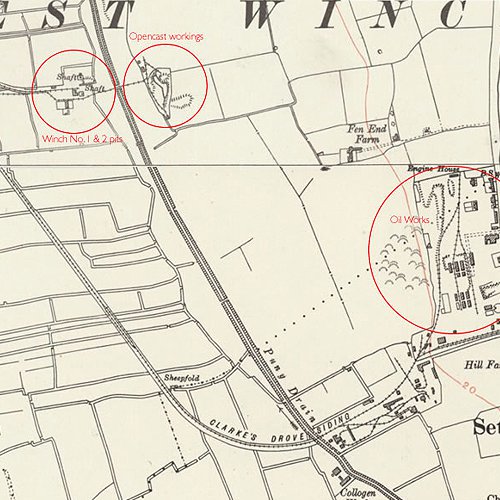

The Kimmeridge oil shales were first found locally where the land had been cut by the Puny drain. Mines and opencast works were subsequently developed in the vicinity. English & Foreign Oil Finance Ltd., who promoted the project, seem to have worked small quantities of shales for testing in experimental retorts near Setch, where gravel deposits provided a suitable foundation for construction of industrial buildings.

English Oilfields Ltd. were launched in 1918 to progress the project and, fronted by the charismatic William Forbes-Leslie, successfully raised substantial capital.

By December 1919, a branch railway (Clarke's Drove siding), had been constructed, linking the works and the shale workings to the Great Eastern Railway main line, almost a mile and a half distant. Plans for a second line linking the works to the Midland & Great Northern Joint Railway at Hardwick, and for an oil pipeline to the docks at Kings Lynn, were never realised. Brickworks were constructed beside the railway to the south of the oil works site to supply construction works.

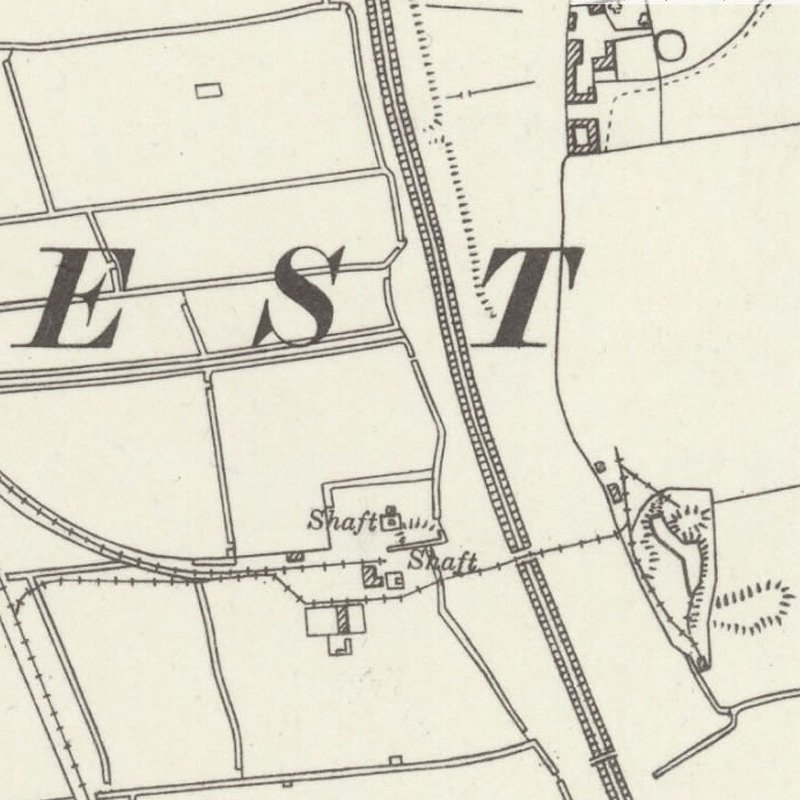

West Winch No.1 shale pit was sunk during 1919: the first licenced mine in Norfolk. At the end of the year it was reported:

"The pit is being continued to 200 ft. and several seams will be mined together. We have found that mining in the shale series is economical and cheap; roofs and floors being available, and the structure of the seams giving natural facilities for mining."

The shafts of No.1 pit (and of No.2 pit begun in 1919), measured 6' x12', and were sunk to a depth of 50ft. It was stated that the headgear, winding engines and compressors for No.1 pit were " on the ground and in the process of erection" at the end of 1919, but it is uncertain whether the either pit was ever completed. The pits were formally abandoned in 1920, it being reported that "the roof is soft so that the walls and roof of the main drifts need to be bricked".

Shale was then worked exclusively from an opencast pit on the east side of the Puny drain. Photographs suggest this was a small-scale operation in which shale was dug by hand, then loaded into wheelbarrows or narrow-gauge railway wagons. There were plans to employ mechanical excavators to work the shale, which would then be transported to the works by aerial ropeway, however it is uncertain whether this mechanisation was ever introduced.

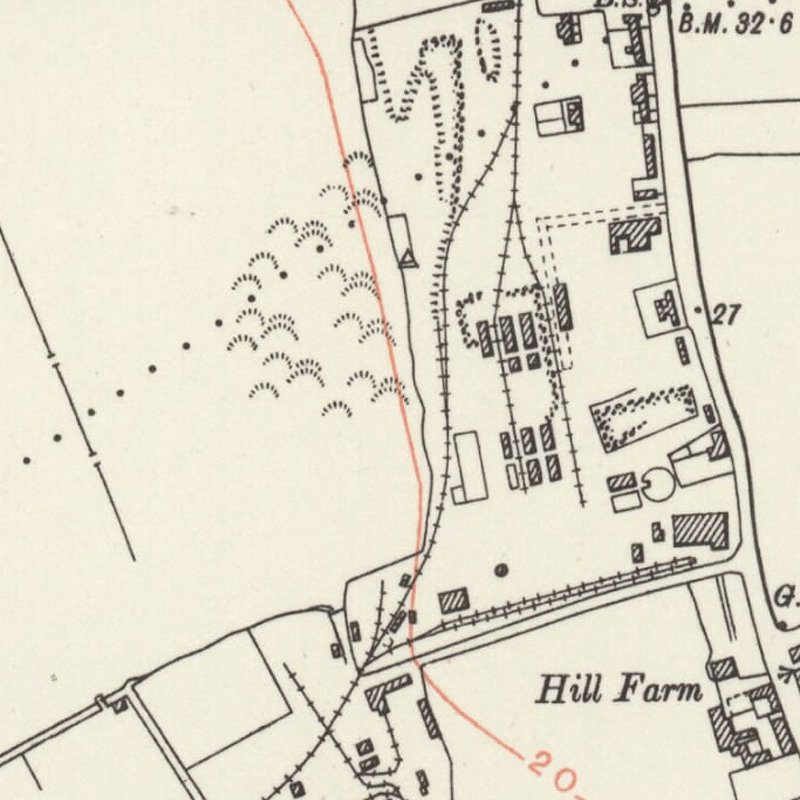

The 25 acre site of the oil works and refinery lay beside the A10 Lynn-Ely Road, adjoining the site of the experimental retorts erected by English & Foreign Finance Ltd. In September 1920 it was reported that a batch of eight retorts were working, An account published in 1920 indicated that three types of retort were then installed at Setch; of the "English Oilfields" , "Fraser", and "Simpson" designs; the first two being developments of the Scottish type of vertical retort. It seems that none of these were particularly effective and in 1920 retorts of the "Black" type were constructed. These also proved unsatisfactory and by 1922 other designs of retort were being trialed.

It appears that the by-product plant (seemingly more suited to a gas works than a refinery?) was completed before the retorts that were to supply them, and consequently would have seen little use. A substantial village of ex-army huts were erected for construction workers.

After about 1926, the company abandoned plans to complete the works and began to dispose of much of the plant on site; however they retained a presence on site until 1966. Aerial photographs from c.1950 show the ruins of many oil works structures remained at that time, including the oil works chimney.

Mapped by the Ordnance Survey of c.1927, showing the relative locations of Setch oil works and West Winch mines.

Number of retorts: More than 8.

Archive images

View looking north from Setch chimney showing test retorts under construction, and the village of workers huts.

Retorts and chimney under construction.

Opencast shale working using wheelbarrows and light railway waggons.

Further view of opencast workings.

All images taken from Kings Lynn and area forums, with great thanks. It seems that some or all of the photographs were saved from destruction by Arthur Ramsome, the last employee of EOL.

There are a railway section, a retorting section, condensing and refining section, the two latter comprehending the works, housing section, a mines section, including the establishment of extensive brickyard, and last, but not extensive shallow and deep drilling section. It was obvious that before construction could be commenced a means transport should be secured. For all intents and purposes the facilities available locally were not for removed from those one might find the South African Veldt; so that we had to build our organisation and create facilities from nothing. A works was selected, adjoining your experimental works 25 acres in extent, where gravels of considerable thickness allowed foundations to be laid. We secured the freehold of this after some difficulty, and you may be congratulated having secured the favourable site for works the neighbourhood. (Hear, hear.)

The Great Eastern Railway were approached with regard a siding from their main line from London, and they assented in principle to our proposal. We have now been able arrange with this company for such siding accommodation: points have been put and connected with our branch the mines and work. The Midland and Great Northern Railway were also approached with view to their granting similar facilities from their line running between Lynn and Peterborough, and we are glad say that they have also agreed to our proposal, and siding accommodations are being linked with the company's branch line from to the company's mines and works. (Hear, hear) We were thus able to begin railway construction. A contract for construction the company's railway from Hardwick Siding on the Midland and Great Northern line, and from St. Jermyn siding, on the Great Eastern line, to your mines at West Winch, and through these and your brickyards the the works at Setch with sidings both at your works, mines, and brickyards, was given, after consideration, to Messrs. Macdonald, Gibbs. and Company, of London. I have great pleasure in bearing witness to the energetic manner in which those contractors have carried out their work. Although the mineral leases cover a part of the ground over which this railway runs, a part was in the hands of small holders, and over all of it tenants had the right of surface. Unfortunately, your railway affected a considerable number these small holders and tenants, and these at first were naturally averse having their lands cut up railway construction. The delays, therefore caused by the negotiations have been considerable. In many the owners absolutely refused, right of way. and were obliged to purchase the land in order to obtain surface facilities. The lands acquired were agriculturally, some the richest in England, and although the price has been, in most cases, high from an agricultural point of view, it very greatly below its value if we include the minerals in such valuation. (Hear, hear.)

The whole the track between West Winch and Hardwick comprehends some of the most valuable mineral land in England. (Applause.) The acquisition of these freeholds has permitted the earth works to be made right into and over the works site; a large number of men have been employed on these and on fencing, track laying, and ballasting. A bridge has been thrown across the Puny Canal and is almost completed, the mines connected with the rail-head and the brickyards, and the means of transport for heavy machinery and material generally have been secured. Considering that work only started in earnest about two months ago, and continued the depth of winter, when the fens are almost you will appreciate the fact that this in itself has been no mean undertaking. (Hear, hear.)

WORKMEN'S CAMP.

The next work essential to undertaking was the erection of workmen's camp. No accommodation is available the neighbourhood. There was no time for the adoption of the Government housing scheme; such work will have to be left for the future, when the works are going and a permanent personnel has settled down the work production. In the meantime the directors were advised to secure Government huts and establish camp. Your managing directors were fortunately able purchase practically complete camp, capable of housing a large number men. This is now elected on the company's freehold Setch, close proximity to the new works, will l»e lighted by electricity, with bathrooms and canteen attached, also reading and recreation rooms and grounds. Great credit due to the hutments manager, Captain Constable, for the very capable way has carried through erection, and for his present management of the camp. The cost of this considerable undertaking has been much less than might have been expected. The price paid for the camp constituted tor tho company a good bargain. With these two essentials perfected - namely the railway and the hutments—the directors are able to deal directly with the object of them- namely, the works construction and the equipment for the mine it was now possible give out contract for the by-product plant, and after a number of firms had been asked to tender the contract finally given to Messrs. Holmes, Huddersfield. The initial contract was to deal with 20,000,000 cubic feet of gas per 24 hours, with power to extend the contract include another 1,.000.000 cubic feet, making total of 30,000.000 cubic feet. The plant consists of annular condensers (atmospheric in principle), surface condensers (tubular type), an adequate number of large exhausters deal with the enormous quantity of gas developed, and then several large tar extractors, and number of washers, ammonia scrubbers, and benzol scrubbers. From this point in its progress the gas goes back to the retorts and power plant, while the crude oil into the refining plant, and the ammoniacal liquor passes into the sulphate plant for treatment. The laying down of the foundations for the by-products plant, and erection of the buildings house and cover the latter, was given to Messrs. Wills, of London. The freehold site was extended by the acquisition of more ground, no that a works site, containing retorts, condensing and refining plant, tankage and distributing sheds, cement works, sulphate of ammonia works, etc., with sidings for adequate truckage, was obtained. The works to placed on this site will be, I believe, the largest retorting, condensing, and refining plant in England. (Applause.)

Another section interest source of future profit was now initiated. I refer to the establishment of large brickyards at West Winch. Bricks are essential materials in the creation a works such as above described, and bricks at the present time are very pensive and difficult to obtain. The discovery on the company's grounds plastic clay, 40ft. thick, was therefore of great importance. the erection of your plant shall require about £100,000 worth bricks, as per market price now obtaining. The establishment your brickyards should save about £50.000 on this one item alone. (Applause.)

The chief saving in cost of manufacture will that can use our own waste gas to fire the bricks. Apart from the needs of the company for bricks, such lessoning of cost of manufacture, which considerable, will allow the company to compete in the open market with advantage in their favour over all rivals. The erection of brick-making plant, kiln*, and machinery to manufacture bricks and pipes in largo quantities now being pressed forward. The company's railway runs right through the brickyards, that transport is available from the company's works all parts of the. United Kingdom (Applause.)

The essentials, therefore, for the erection of a large oil producing works have been secured, and that, in my opinion, small outlay. This is especially a matter for congratulation. (Hear, hear.)

The mines at West Winch and the scheme of mining development generally will now occupy our attention. No. pit, after having paced through several large seams, has reached a scam of 11ft in thickness, upon which driving is proceeding at satisfactory rate. West Drive is now under the site of the upcast shaft, which has been designed lift 1,000 tons per day. Sinking upon No.2 shaft is now beginning, and it will continue down to meet the drive from No. 1 pit. and continue thence to the 250 ft. level, where one of the largest and most productive seams of the whole measures is situated. The equipment for this shaft is order. All the equipment for No.2 pit - namely, headgear, winding engines, compressors, etc. have been purchased and are on the ground or process of erection. (Applause.) The lay-out between the mine West Winch and works at to co-ordinate the two departments drafted. Aerial ropeways will connect the two, being the means for transporting the shale from the mine to the works through special storage bunkers.

Yorkshire Post, 31st December 1919.

.......

A Visit to the Norfolk Shale Fields.

Development Operations in Full Swing

The development of the Norfolk fields is proceeding with great rapidly and according to the Petroleum Times, the production of home oil on a commercial scale will be possible before the end of the year. It appears that the whole agricultural aspect of the north-western portion of Norfolk has been changed, and presents today presents quite an industrial appearance. A large mining camp has been erected, and already there is accommodation in this for some workers on the fields. Streets have been out, a septic system sewage adopted, and electric light connected to all the hutments. In addition to the energetic arrangements for the early operation of the shales in large quantities, a deep well for liquid oil is being drilled, and a depth of 300 feet has been reach, the impression of the geologists being that beneath the shale deposits lie large reserves of oil. Within the next three months, shafts are to sunk for the liquid, and if necessary, a depth of 4,000 feet can be reached. Numerous permanent buildings are being built on the shale fields, a large deposit of fine gravel enabling the English Oilfields Ltd. which controls the whole of the areas, to manufacture concrete blocks the spot. In addition a plastic clay deposit is also to be utilised. It is anticipated that this will permit the manufacture of bricks for other than the company's needs.

The special branch from the Great Eastern Company's main line is now completed, and thus the transport of material for the refining and condensing works at Setch is greatly facilitated. As a result of further investigations English Oilfields Ltd. has secured additional leasehold of lands the neighbourhood of King's Lynn its total holdings are now considerably over 140 square miles. Contrary to original plans it has been decided to limit the shale operations to a very rich eleven foot seam of shale which has been located at about 70ft. from the surface. This deposit alone will keep the Company fully occupied for several years to come. The seam which has only recently been discovered, contains over 80 gallons of crude oil to the ton of shale treated in addition to enormous quantities of gases, which will available for cheap power sources. Indeed, this portion of Norfolk, has every appearance developing into one of England's large industrial centres for ample cheap power to-day is a greater factor than ever.

Cambridge Daily News, 2nd March 1920.

Recent images

The site of Setch Oil Works. Looking West. July 2015.

The site of Setch Oil Works. Looking South West. July 2015.

The site of Setch Oil Works. Looking West. July 2015.

- The Norfolk Oil Rush 1916-1921, by R.W. Gallois, Proceedings of the Geologists Association,Volume 123, Issue 1, January 2012, Pages 64–73

- Kings Lynn Forums - The Setch Oilfields